Introduction

In Indian industries, cable management isn’t something people think about until it causes a problem. Whether it’s a chemical plant in Gujarat or a thermal power station in Tamil Nadu, the challenge is always the same: cables need to be routed safely and reliably, and the trays holding them need to survive some pretty brutal conditions.

For years, metal trays were the default choice. They were strong, familiar, and did the job until corrosion kicked in. That’s when companies started looking for something better. And many of them found their answer in fiberglass cable trays.

Unlike steel, fiberglass doesn’t rust. It doesn’t give up under coastal humidity, harsh chemicals, or punishing heat. More importantly, it’s easier to handle, safer around electricity, and lasts longer with far less maintenance. These aren’t small upgrades they’re big improvements that make a difference over time.

This piece takes a close look at how Fiberglass Cable Trays India are changing the game not in theory, but out there in the field, where the real work happens.

Built to Beat Corrosion

India’s factories and plants face some brutal environments, from coastal humidity to chemical spills. Fiberglass cable trays hold their own where others rust away, thanks to their corrosion-resistant design.

Standing Up to Chemicals

Fiberglass cable trays, made of polyester or vinyl ester resins reinforced with glass fibers, are indelibly resistant to the whole-spectrum of chemicals going from acids, alkalis to organic solvents. In the chemical hubs of India like Gujarat and Maharashtra, where plants are handling substances like sulfuric acid and caustic soda, FRP trays not only hold up structurally but also do not get to the point of rust or degradation. To illustrate, a fertilizer plant in Paradeep, Odisha, informs us that FRP cable trays have been soaring during corrosion conditions for over 20 years, on the other hand, steel trays have been replaced every 5–7 years with rust being the only reason.

Rocking It on the Coast

With 7,500 kilometers of coastline, India’s got ports, shipyards, and offshore rigs in places like Mumbai and Chennai that face constant saltwater and humidity. Fiberglass trays don’t flinch at saline corrosion, UV rays, or moisture. An offshore platform in the Arabian Sea cut maintenance costs by 30% after switching to FRP trays, which held up where stainless steel started to crumble. That’s a big win for coastal projects dealing with relentless weather.

Practically No Maintenance

Metal trays require perpetual painting or replacement to combat rust. Fiberglass trays? They simply never stop. Jamnagar, Gujarat-based petrochemical plant reduced maintenance downtime by 40% using FRP trays, saving time and money. For manufacturing units racing to achieve production goals, that low-maintenance feeling is a life saver.

Light, Tough, and Easy to Work With

Weighing about a third of steel trays, fiberglass cable trays make moving and setting up cables a whole lot easier, especially for India’s massive industrial projects.

Cheaper to Ship, Easier to Move

Getting heavy materials across India’s diverse terrain deserts in Rajasthan, hills in the Northeast can be a headache and a half. FRP trays, being so light, cut transport costs. A solar plant in Rajasthan’s Thar Desert saved 25% on shipping by going with fiberglass instead of steel, which really matters in remote spots with shaky infrastructure.

Quick to Install

Lighter trays mean faster setups with fewer hands-on deck. A data center in Bengaluru got FRP trays up 30% quicker than steel, saving on labor and speeding up the project. Plus, they’re easy to cut or drill on-site, fitting into tricky layouts without needing fancy tools, like in a Pune factory’s complex setup.

Less Stress on Structures

For bridges, tunnels, or high-rise plants, keeping weight down is key. FRP trays, with their high strength-to-weight ratio, take the pressure off support systems. A Kolkata bridge project used fiberglass trays for communication cables, cutting the need for extra structural supports and saving 15% on construction costs.

Keeping Things Safe

In India’s high-risk industries, where electrical faults or fires can cause chaos, fiberglass cable trays bring serious safety advantages.

No Electrical Worries

Metal trays can conduct electricity, risking shocks or short circuits. FRP trays don’t, making them safer for high-voltage setups. A Tamil Nadu power plant switched to fiberglass, skipping complicated grounding systems and making maintenance safer for workers.

Fire-Resistant Design

By the virtue of their flame-retardant characteristics, fiberglass trays are compliant with the UL 94 V-0 standard that is a very stringent requirement. In a Surat textile factory, FRP trays contained a minor electrical fire and did not allow it to reach the vital parts of the wiring; hence, the factory was not forced to stop its operation and pay for the idle time. The tentacles of fire are never far away in such places as an oil and gas plant, so take all the necessary precautions.

Tough Against the Sun

India’s intense sunlight, especially in spots like Andhra Pradesh, can wear materials down. FRP trays, packed with UV inhibitors, stay strong under constant sun. A solar farm in Andhra Pradesh ran fiberglass trays for a decade with no signs of wear, while metal trays started fading and cracking.

Saving Money in the Long Run

Sure, fiberglass trays might cost a bit more upfront than steel, but their long-term savings make them a smart pick for cost-conscious industries.

Easier on the Budget for Setup

Lightweight FRP trays need less labor and fewer supports. A Pune factory cut installation costs by 20% with fiberglass, using fewer workers and simpler setups. That’s huge for projects with tight budgets.

Lasting for Decades

FRP trays can go 20–30 years, even in rough conditions, compared to 5–10 years for galvanized steel. A Delhi wastewater plant hasn’t touched its fiberglass trays in 15 years, saving big bucks compared to steel’s constant replacements.

Running Lean on Energy

FRP’s non-conductive, heat-stable design keeps cables cool, cutting energy loss. A Hyderabad data center dropped cooling costs by 10% with fiberglass trays, which kept cables at the right temperature.

Fitting Every Industry’s Needs

From refineries to renewables, fiberglass cable trays adapt to whatever India’s industries throw at them.

Keeping Chemical Plants Running

In corrosive setups like refineries, FRP trays protect cables without fail. A Vadodara refinery’s ladder-type fiberglass trays held up heavy power cables for over a decade with zero corrosion, keeping things running smoothly.

Powering Up Renewables

India’s gunning for 500 GW of renewable energy by 2030, and FRP trays are a perfect fit. Their lightweight, corrosion-resistant build suits solar and wind projects. A Tamil Nadu wind farm used fiberglass trays for control cables, cutting install time by 25% and standing strong in coastal winds.

Cooling Data Centers

India’s IT boom, with data centers in Mumbai and Bengaluru, needs smart cable management. Perforated FRP trays, built for airflow, stop cables from overheating. A Bengaluru data center got 15% more life out of its cables thanks to fiberglass’s heat-dissipating design.

Supporting Big Projects

Bridges, tunnels, and metros love FRP’s durability and light weight. The Chennai Metro used fiberglass ladder trays for communication cables, reducing structural weight and saving 20% on install costs.

Going Green the Smart Way

With India pushing for sustainability, fiberglass cable trays fit right in, offering real environmental perks.

Recyclable and Energy-Wise

FRP trays are recyclable, and their pultrusion process uses less energy than metal production. A Chennai factory cut its cable system’s carbon footprint by 18% with fiberglass, making operations greener.

Hitting Green Building Goals

FRP trays help projects meet IGBC and LEED standards with their long life and low upkeep. A Gurugram commercial complex boosted its LEED rating with fiberglass trays, cutting waste and maintenance needs.

Standing Up to Nature

From salty coastal air to heavy rains, FRP trays don’t break down, reducing replacements. A Karnataka coastal power plant’s fiberglass trays held strong despite constant exposure, keeping waste low and infrastructure sustainable.

Custom-Built for Tough Jobs

Fiberglass trays are flexible enough to handle India’s trickiest industrial setups, making them a top choice.

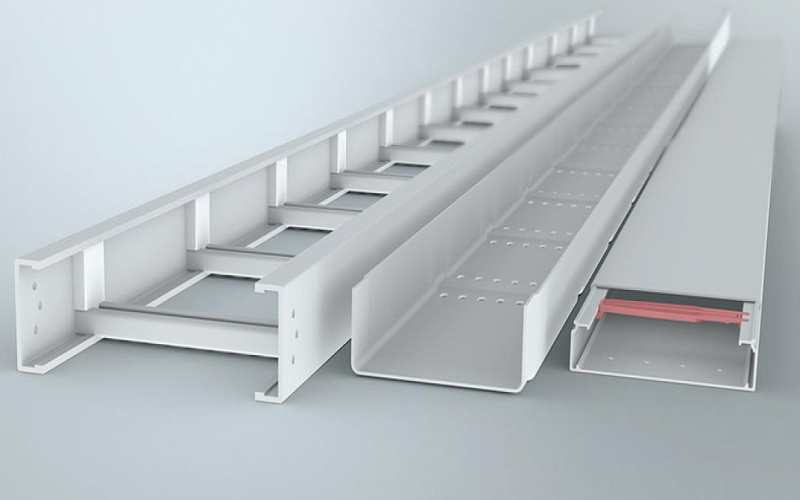

Shaped for Any Project

Pultrusion lets FRP trays be molded into ladder, perforated, or solid-bottom designs. Fiber Tech Composite Pvt Ltd builds custom solutions for India’s toughest projects. Their ladder trays tackle heavy refinery loads, while perforated ones keep data centers cool.

Color-Coded for Efficiency

FRP trays can be colored to blend with plants or mark cable types. A Hyderabad pharma plant used color-coded fiberglass trays to separate power and control cables, speeding up maintenance by 15%.

Fitting Tight Spaces

With fittings like bends and tees, FRP trays slide into complex systems. A Delhi metro project used custom fiberglass fittings, cutting install time by 20% in cramped spots.

Facing Challenges Head-On

Fiberglass trays are great, but there are a few hurdles to clear for top performance.

Weighing the Upfront Cost

FRP trays can cost more than steel at first, but the savings add up. A Jharkhand steel plant broke even on fiberglass trays in 3 years, thanks to lower maintenance costs.

Handling Heavy Loads

For super heavy-duty jobs, FRP might not match steel. A Punjab machinery plant used hybrid FRP-steel systems to balance strength and corrosion resistance, showing the need for careful planning.

Getting the Install Right

Proper spacing and supports are a must for FRP trays. An Uttar Pradesh chemical plant had sagging issues from bad installs, proving skilled workers and manufacturer guidelines are key.

What’s Coming Next

Fiberglass trays are set to play a bigger role in India’s industries, with new tech and demands pushing them forward.

Smarter Cable Systems

Sensor-equipped FRP trays are starting to track cable health and conditions. A Pune smart factory tested these, cutting downtime by 10% by catching overheating early.

Better Manufacturing

New pultrusion tech is making FRP trays tougher and cheaper. Companies like Fiber Tech Composite Pvt Ltd are using automation to produce top-notch trays, supporting India’s Make in India push.

Powering Smart Cities

India’s smart cities and renewable projects will lean on FRP trays for their light, durable build. Gujarat’s smart city networks already use fiberglass trays for communication cables, setting the stage for modern infrastructure.

Wrapping It Up

FRP cable tray exporters are revolutionizing cable management, solving India’s most challenging industrial problems with finesse. They resist corrosion, keep safe, save money, and reduce carbon footprint, making them ideal for chemical plants, renewables, data centers, and large projects. With the likes of Fiber Tech Composite Pvt Ltd at the forefront, fiberglass trays are leading the way to a stronger, smarter industrial India.