In industries where corrosion resistance, high pressure handling, and long-term durability are critical, stainless steel ball valves have become the go-to solution for efficient flow control. As a result, stainless steel ball valve manufacturers in India are witnessing rising demand both domestically and internationally. Combining advanced engineering, international quality standards, and cost-effective production, these manufacturers offer premium valve solutions for a wide range of industrial applications.

Why Stainless Steel Ball Valves?

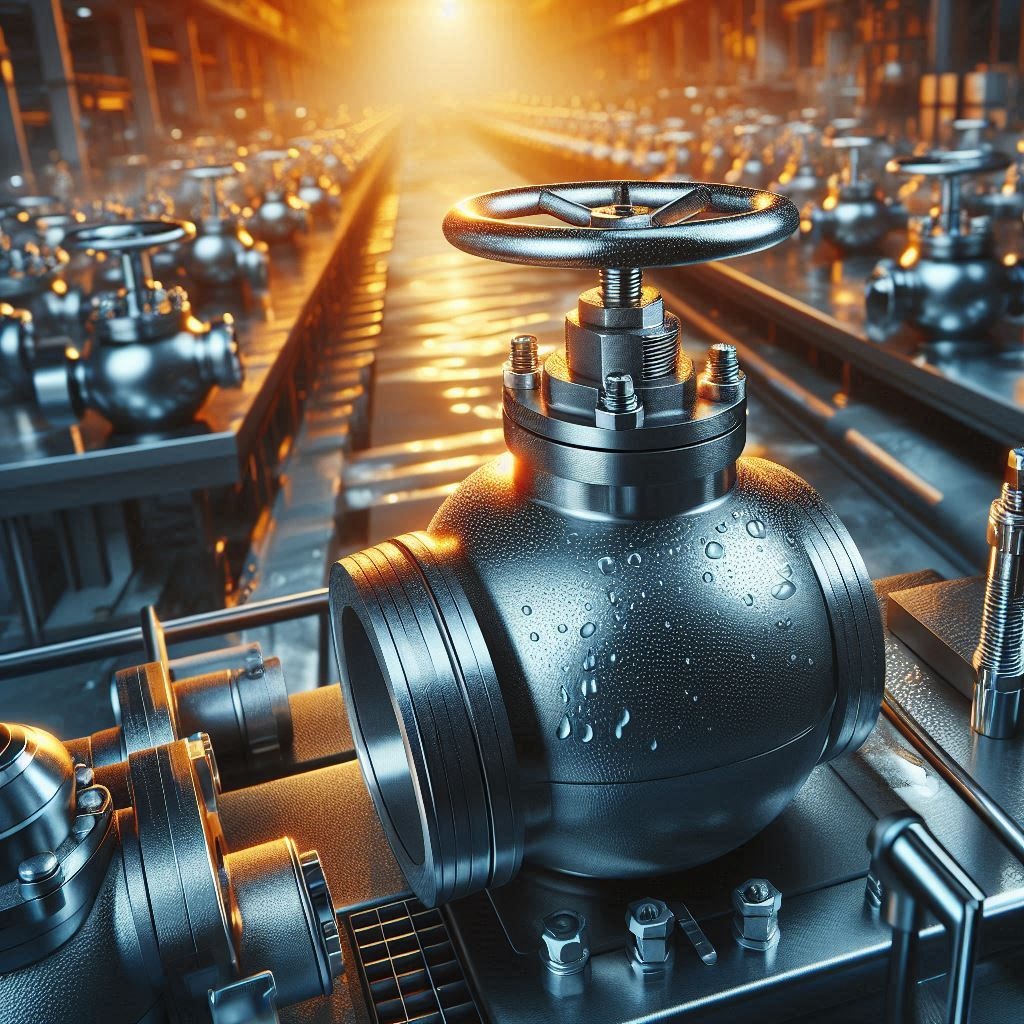

Stainless steel ball valves are renowned for their exceptional strength, corrosion resistance, and reliable performance across a wide temperature range, making them ideal for critical applications involving aggressive fluids, chemicals, and gases. Their durability and leak-proof, low-torque operation make them a preferred choice in demanding industries such as oil & gas, chemical processing, water treatment, food & beverage, pharmaceuticals, marine and offshore, and pulp & paper. Manufactured in high-grade materials like SS304, SS316, and duplex stainless steel, these valves are engineered to withstand harsh operating conditions while maintaining consistent flow control and long service life.

India’s Leading Manufacturers: Quality You Can Trust

Top stainless steel ball valve manufacturer follow strict quality control practices and manufacture valves in compliance with global standards such as API, ISO, ANSI, and BS. With in-house capabilities for CNC machining, pressure testing, and material certification, these manufacturers guarantee valves that meet exacting industrial requirements.

Key Features Offered

Stainless steel ball valve manufacturers in India offer a versatile range of products designed to meet the diverse needs of global industries. These valves are available in premium material grades such as SS304, SS316, CF8M, CF3M, and duplex stainless steel, ensuring exceptional corrosion resistance and durability in demanding environments. With options including 2-way, 3-way, full-port, reduced-port, floating, and trunnion-mounted designs, manufacturers cater to various flow control applications. All valves are certified to international standards like ISO 9001, API 6D, PED, ATEX, and CE, reflecting a strong commitment to quality and safety. Offered in sizes ranging from ½” to 24” and pressure classes from PN10 to PN100 (Class 150 to 900), these valves come with multiple end connections such as flanged, threaded, socket weld, and butt weld, providing maximum flexibility for system integration.

Customization & Application Support

Indian manufacturers also provide custom-engineered stainless steel ball valves tailored to specific pressure, temperature, and flow requirements. Whether it’s for high-purity pharmaceutical applications or corrosive chemical lines, these valves are built with precision to deliver maximum safety and performance. Most manufacturers also offer on-site technical support and quick delivery timelines.

Global Reach & Export Excellence

Thanks to world-class manufacturing facilities and competitive pricing, stainless steel ball valve manufacturers in India are now exporting to over 50 countries including the USA, UAE, Germany, Australia, and Singapore. Their valves are used in major industrial projects, EPC contracts, and OEM applications around the world.

Conclusion

If you’re looking for reliable, high-quality stainless steel ball valves, partnering with a trusted manufacturer in India ensures superior performance, global compliance, and long-term value. With a perfect blend of technical expertise, production capacity, and customer support, Indian stainless steel ball valve manufacturers are helping industries around the globe achieve safe and efficient flow control.