Steel is an adaptable material that has brought about a breakthrough in the building and construction sector. The usage of this material may be seen in anything from skyscrapers to commonplace home goods. Because of its strength, steel is considered to be one of the most significant characteristics. On the other hand, how do engineering professionals and manufacturers estimate the strength of steel? It is at this point that the tensile test is performed. One of the most important methods for determining the strength of steel and other materials is the tensile test. The extreme amount of stress that a material is capable of surviving before it breaks may be determined with the support of this test by engineers and producers.

What is tensile testing?

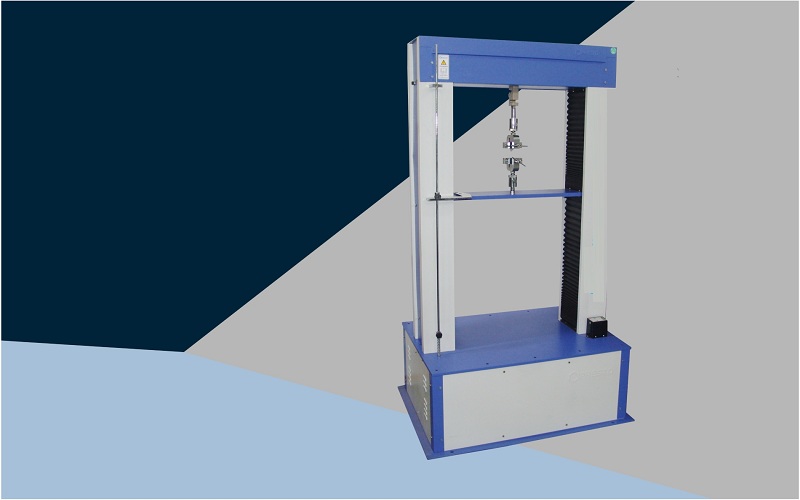

In the realm of steel testing, the tensile test is among the most well-known tests. The standard EN 10 002 acts as a representation of the test. During the test, a test piece is subjected to tensile force, which causes it to fracture. This is done in order to determine the stiffness, yield quality, and occasion of the material. Reducing the zone area while maintaining pliability. For the purpose of determining attributes such as young’s modulus, extreme quality, and rate prolongation, tension tests are carried out on mild steel, tor steel, and high tensile steel for the purpose of tension testing. In the strain test, a steel pole is subjected to tension stress from a universal testing machine. This is done in order to determine the strain.

Range of Tensile testing machine Manufacturers India

- Ductile wedge and hub shape

Because of its wedge and hub form, which makes installation and maintenance both simple and straightforward, they are a popular option for a wide variety of applications. Due to the excellent strength and resistance to corrosion that the ductile iron material that is used in these fittings has, they are able to provide long-term performance even in settings that are very demanding.

- Quality of locks that are full-size products

When it comes to making the overall performance and endurance of these crucial hardware components, the full-size yield quality of latches is an important criteria to take into consideration. Also while it comes to choosing latches for a diversity of apps, such as doors, cabinets, or gates, it is of the highest importance to assure a high-quality output.

- Testing of welds and castings using ductile materials

Within the areas of material science and engineering, ductile testing of repairs and castings is an important technique that must be detected. This kind of testing determines whether or not a material is capable of undergoing plastic deformation without breaking under the influence of tensile stress.

- Tubing that is all-size

Engineering professionals make use of specialized apparatus in order to imitate circumstances that are seen in the real world and evaluate how the tubing will behave in a variety of product strength situations.

- Testing of ductility at elevated temperatures

During the process of raised temperature ductile testing, a material is subjected to high temperatures in order to assess its ductility, which may be defined as the capacity to exhibit deformation without breaking.

At the end, the significance of conducting tensile tests on steel cannot be emphasized by any means. The evaluation and confirmation of steel qualities are both significantly aided by its position as a cornerstone.

Conclusion

In general, “Force of Steel machine offers is an example of the progress that has been made in the area of materials testing technology and the important role that it plays in the processes of modern manufacturing services. Because of its correctness, trustworthiness, and adaptableness, it is a vital tool for engineers, investigators, and quality control authorities who are interested in comprehending and improving the mechanical characteristics of materials. Tensile testing machine India will remain to be at the forerunner of materials testing as technology endures to advance, hence encouraging innovation and superiority across a variety of manufacturing sectors.